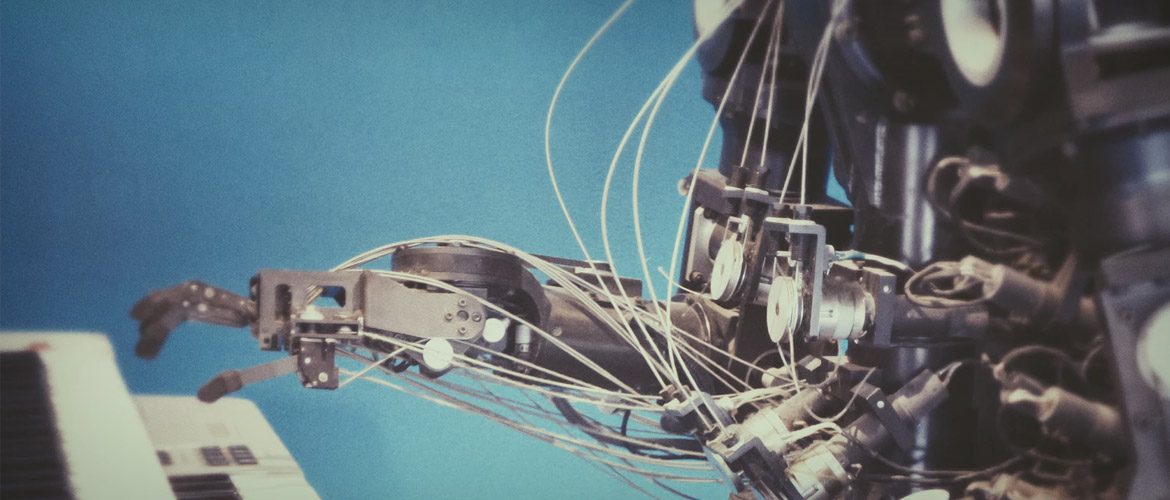

Industry 4.0 is a name given to the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things, cloud computing and cognitive computing.Industry 4.0 is commonly referred to as the fourthindustrial revolution.

Industry 4.0 is the paving the path for digitization of the manufacturing sector, where artificial intelligence (AI) and machine-learning based systems are not only changing the ways we interact with information and computers but also revolutionizing it.

Compelling reasons for most companies to shift towards Industry 4.0 and automate manufacturing include;

- Increase productivity

- Minimize human / manual errors

- Optimize production costs

- Focus human efforts on non-repetitive tasks to improve efficiency

Manufacturing is now being driven by effective data management and AI that will decide its future. The more data sets computers are fed, the more they can observe trends, learn and make decisions that benefit the manufacturing organization. This automation will help to predict failures more accurately, predict workloads, detect and anticipate problems to achieve Zero Incidence.

ZIF’s proprietary AIOps based TechOps platform – ZIF can successfully integrate AI and machine learning into the workflow allowing manufacturers to build robust technology foundations.

To maximize the many opportunities presented by Industry 4.0, manufacturers need to build a system with the entire production process in mind as it requires collaboration across the entire supply chain cycle.

Top ways in which ZIF’s expertise in AI and ML are revolutionizing manufacturing sector:

- Asset management, supply chain management and inventory management are the dominant areas of artificial intelligence, machine learning and IoT adoption in manufacturing today. Combining these emerging technologies, they can improve asset tracking accuracy, supply chain visibility, and inventory optimization.

- Improve predictive maintenance through better adoption of ML techniques like analytics, Machine Intelligence driven processes and quality optimization.

- Reduce supply chain forecasting errors and reduce lost sales to increase better product availability.

- Real time monitoring of the operational loads on the production floor helps in providing insights into the production schedule performances.

- Achieve significant reduction in test and calibration time via accurate prediction of calibration and test results using machine learning.

- Combining ML and Overall Equipment Effectiveness (OEE), manufacturers can improve yield rates, preventative maintenance accuracy and workloads by the assets. OEE is a universally used metric in manufacturing as it combines availability, performance, and quality, defining production effectiveness.

- Improving the accuracy of detecting costs of performance degradation across multiple manufacturing scenarios that reduces costs by 50% or more.

Direct benefits of Machine Learning and AI for Manufacturing

The introduction of AI and Machine Learning to industry 4.0 represents a big change for manufacturing companies that can open new business opportunities and result in advantages like efficiency improvements among others.

- Cost reduction through Predictive Maintenance that leads to less maintenance activity, which means lower labor costs, reduced inventory and materials wastage.

- Predicting Remaining Useful Life (RUL): Keeping tabs on the behavior of machines and equipment leads to creating conditions that improve performance while maintaining machine health. By predicting RUL, it reduces the scenarios which causes unplanned downtime.

- Improved supply chain management through efficient inventory management and a well monitored and synchronized production flow.

- Autonomous equipment and vehicles: Use of autonomous cranes and trucks to streamline operations as they accept containers from transport vehicles, ships, trucks etc.

- Better Quality Control with actionable insights to constantly raise product quality.

- Improved human-machine collaboration while improving employee safety conditions and boosting overall efficiency.

- Consumer-focused manufacturing: Being able to respond quickly to changes in the market demand.

Touch base with ZIF AI experts here: https://zif.ai/ and see how we can help you drive your manufacturing operation towards Industry 4.0.